A little dust? Maybe not a big deal in everyday life, but in space dust is more than just a cosmetic problem. And dust is not only present on Earth, but also on all other terrestrial planets – and their moons. Our Earth's moon in particular is covered all over with dust. And unlike on Earth, this dust is not polished smooth by wind and weather, but sharp-edged and electrostatically charged. This was also the experience of the Apollo astronauts who, after their stay on the surface, had to struggle not only with defective zips on their space suits but also with irritated respiratory tracts. In some cases, the discomfort lasted far beyond the end of the mission. In this interview, Dr Axel Müller, Lead Expert Cleanliness and Contamination Control at OHB System AG, explains how astronauts and equipment can be protected from harmful particles and what options there are for making good use of the lunar dust.

Dr Müller, why is lunar dust such a big problem?

Axel Müller: First of all, you have to realise the amount of dust you are dealing with on the Moon. We are not talking about individual particles here, but a layer up to fifteen metres thick. Moreover, lunar dust has some properties that make it particularly unpleasant. People always talk about dust, but this picture is actually not quite right. Lunar regolith is pulverised lunar rock and in many ways is more like sand. However, since the Moon has no atmosphere, the individual particles are not rounded, but sharp-edged. Additionally, due to the brief exposure to heat during asteroid impacts, the regolith is interspersed with glass splinters. On the surface, the sand is very fine, but in deeper layers, larger stones and rocks also occur. Due to the low gravity on the Moon, swirled-up particles only sink back to the surface very slowly, and the solar radiation charges the particles electrostatically, causing them to adhere particularly firmly to surfaces.

What does this mean for exploration missions to the Moon?

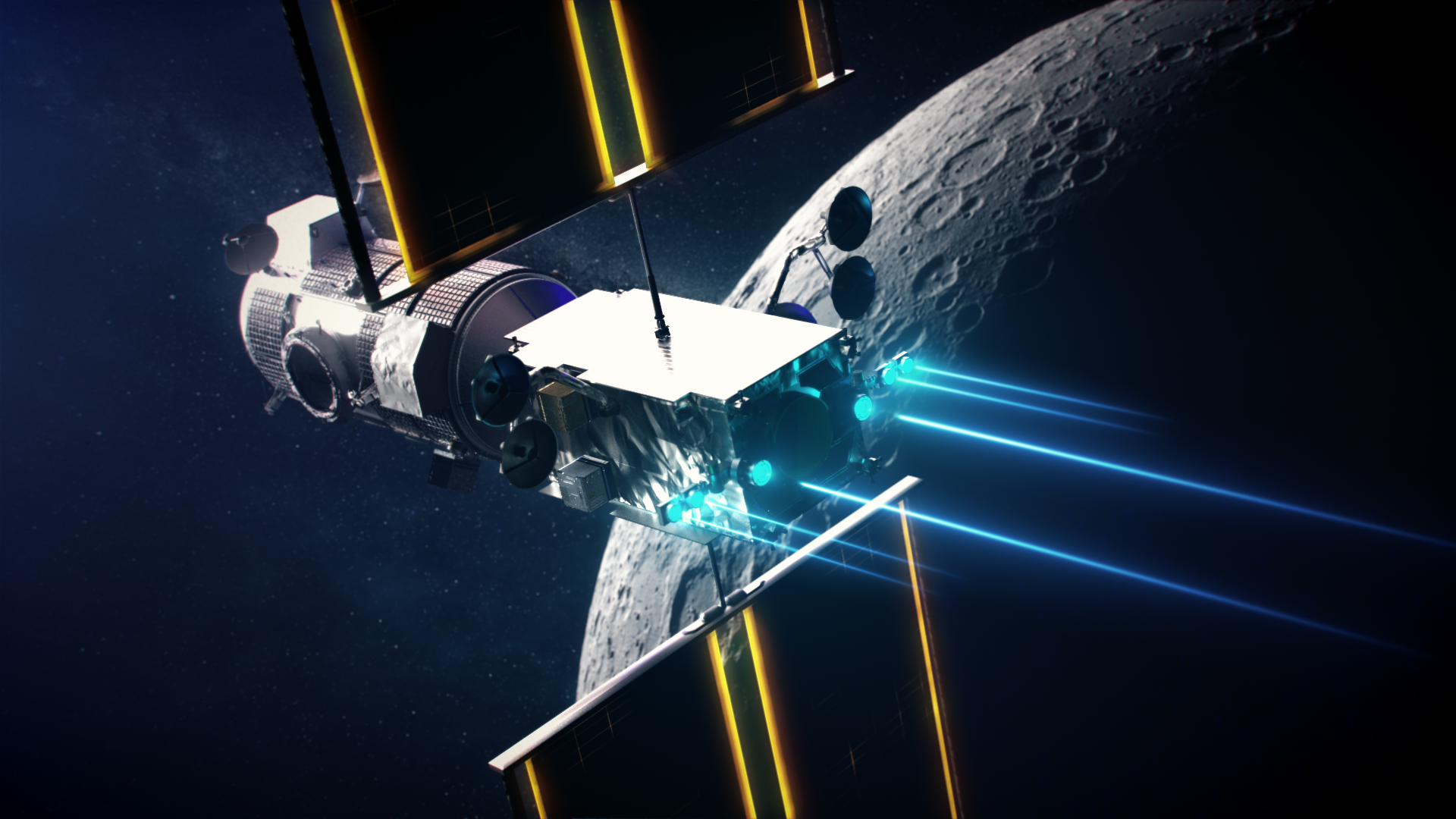

It means that our standard methods of avoiding contamination on technical components are not applicable. It is not for nothing that NASA, in a 2005 study, ranked dust as the biggest challenge for future lunar missions. The dust can get into seals and mechanical components and drastically shorten their service life by affecting their frictional properties. It can also contaminate optics and settle on solar cells and thermal radiators, causing them to generate less energy or give off less heat. A good example of this is NASA's Mars rover Opportunity, which eventually fell victim to a dust storm after a 15-year long mission.

Is lunar dust also dangerous for humans?

Yes, in two respects: On the one hand, the dust can damage the seals of space suits and airlocks due to its sharp edges. During the Apollo missions, for example, the astronauts' zips were no longer functional after a very short time. In addition, the dust adheres to all surfaces due to the electrostatic charge and it is therefore almost impossible to avoid it getting into interior spaces. There, the lower gravity causes dust particles to remain suspended in the air for much longer. In addition, the protective reflex of the eye does not function in the lunar environment as it does on Earth. The Apollo astronauts experienced first-hand that breathing in the dust or getting it into their eyes was not exactly good for their health. After returning from the lunar surface, they all suffered from irritated airways and eyes, a kind of "lunar hay fever", as they called it.

What are the options for meeting the challenge posed by the dust?

To tackle this challenge, ESA has just commissioned a study. It is called DEAR - Dusty Environment Application Research. It is a project with academic and industrial partners from Germany, Austria, Ireland, Norway, Romania, France and Belgium. The aim of the study is to find ways to remove dust deposits on optical surfaces, mechanisms and seals or to avoid them altogether. To this end, in addition to mechanical methods, the possible applications of electric fields are being investigated, among other things. Furthermore, cleaning methods for airlock systems are being investigated. Another approach is to design systems so robustly from the outset that dust plays no role.

What role does OHB have in the study?

As the initiator of the project, OHB is acting in an advisory capacity and leads the space activities. In addition to that, we are responsible for quality control and cleanliness. The focus is on understanding the existing challenges, the sound formulation of requirements and their verification. We also link the activities to ongoing or planned tenders within the OHB Group. We work on testing and cleaning procedures for equipment on Earth and the Moon and test them with regolith simulants produced in the consortium.

Where does the expertise relevant to this role come from?

Assessing and dealing with possible contamination by particles is one of the core tasks of the Cleanliness department at OHB. We carry out risk analyses, define requirements, take measurements and evaluate results on a daily basis and, of course, draw the appropriate conclusions. It has to be said, however, that in our day-to-day business we are primarily concerned with the conditions in clean rooms. Compared to the surface of the Moon, conditions there are of course almost paradisiacal. But we assume that dealing with dusty environments will play a decisive role in future proposals. Especially for future surface missions to the Moon and Mars. Through our various network partners, we can contribute our expertise in different areas. Examples are the simulation of regolith properties, the development of space suits or space medicine. Our long-standing contacts with geologists and volcanologists and their experience with pyroclastic rocks help us enormously here.

Are there also possibilities to use the lunar dust?

Since lunar dust is available in almost unlimited quantities, this is an obvious idea. There are promising approaches to extract oxygen and raw metal from regolith, and the use of lunar dust as a storage medium and building material is also being intensively investigated. We are also involved in a study that aims in this direction: LARS - Lunar Regolith Application Study. The study is about understanding the properties of regolith and ensuring that processing methods developed on Earth are properly evaluated, compared and approved. This involves, for example, the individual phases in the 3D printing of regolith.

How is OHB involved in this study?

We are supporting the development of realistic requirement profiles for the 3D printing process and have set ourselves the goal of establishing measurement methods to precisely define and verify these requirements. This is a necessary step to achieve flight clearance for hardware. Overall, we look at both sides of the coin when it comes to lunar dust: in the DEAR project, we see lunar dust as a challenge, whereas in LARS it represents a valuable resource that must be used in the best possible way.

Dr. Axel Müller holds a degree in physics and a doctorate from the Technical University of Munich. After completing his doctorate, he worked for three years as a post-doctoral researcher at Stanford University in California in the USA before joining Kayser-Threde in Munich (part of OHB System AG since 2014) as the first Cleanliness Engineer. In the following years, he established the Cleanliness department within the OHB Group as part of Quality Assurance and is now Lead Expert Cleanliness and Contamination Control.